About Pinnacle Precision Technology

Pinnacle Precision Technology stands as a dedicated provider committed to delivering cost-effective, yet exceptionally high-quality precision stampings. Our operational strength is anchored by cutting-edge equipment, empowering us with the versatility to furnish components to a diverse spectrum of industries and markets spanning the greater Midwest. Our comprehensive suite of specialized services encompasses Stamping, Laser Cutting, Fabrication, Machining, Wire Electrical Discharge Machining (EDM), and Computer Numerical Control (CNC) Turning. Whether the project demands low or high production volumes, our customers can consistently expect the highest level of expertise and meticulous attention to detail.

Pinnacle Precision Technology stands as a dedicated provider committed to delivering cost-effective, yet exceptionally high-quality precision stampings. Our operational strength is anchored by cutting-edge equipment, empowering us with the versatility to furnish components to a diverse spectrum of industries and markets spanning the greater Midwest. Our comprehensive suite of specialized services encompasses Stamping, Laser Cutting, Fabrication, Machining, Wire Electrical Discharge Machining (EDM), and Computer Numerical Control (CNC) Turning. Whether the project demands low or high production volumes, our customers can consistently expect the highest level of expertise and meticulous attention to detail.

Since its establishment in 1953, Pinnacle Precision Technology has cultivated a rich legacy in providing superior stamping services. Our extensive industry experience allows us to cater to a broad array of sectors, including Lighting, Aerospace, Thermal and Heat Transfer, Agriculture, Construction, Industrial, Water and Recreation, Automotive and Customer Displays. We possess the proficiency to work with a wide variety of materials, including steel, aluminum, stainless steel, brass, and copper, ensuring we can meet the unique requirements of each customer request. Proudly located in Wisconsin, Pinnacle Precision Technology benefits from a long-standing history, a distinguished reputation for excellence, and a robust base of loyal customers who trust in our consistent quality and reliability.

At the core of our operations are our dedicated employees, who approach every project with an unwavering commitment to perfection. We embrace challenges as opportunities to demonstrate our capabilities and ingenuity. Our guiding principle is to consistently "close the gaps between what we say and what we do," underscoring our deep commitment to our clients. We maintain a laser-like focus on customer satisfaction, ensuring that our clients' needs and expectations are always our top priority. We approach each and every job with the dedication and meticulousness as if it were our most important undertaking.

Committed To Quality

Our commitment to quality is formalized in the following policy:

Pinnacle Precision Technology aspires to be a preeminent manufacturer of Precision Machined, Fabricated, Welded, and Stamped Metal Components.

This policy is adhered to through a process of continual quality improvement, achieved via diligently monitored processes and well-coordinated quality and management actions. These efforts are specifically designed to ensure our customers receive products and services of the highest possible quality. Furthermore, Pinnacle Precision Technology is fully committed to satisfying all applicable requirements stipulated by ISO 9001:2015 and its associated quality objectives. It is the responsibility of all personnel at Pinnacle Precision Technology to strictly adhere to the requirements outlined within this commitment to quality.

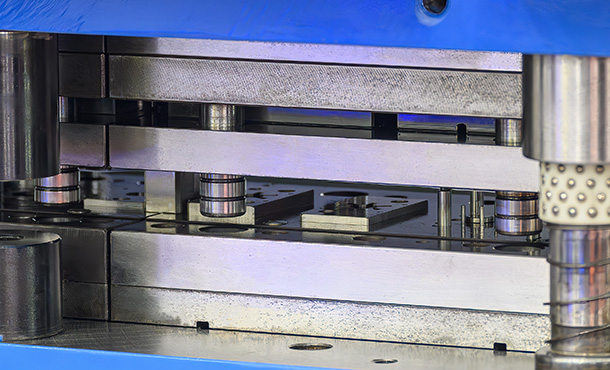

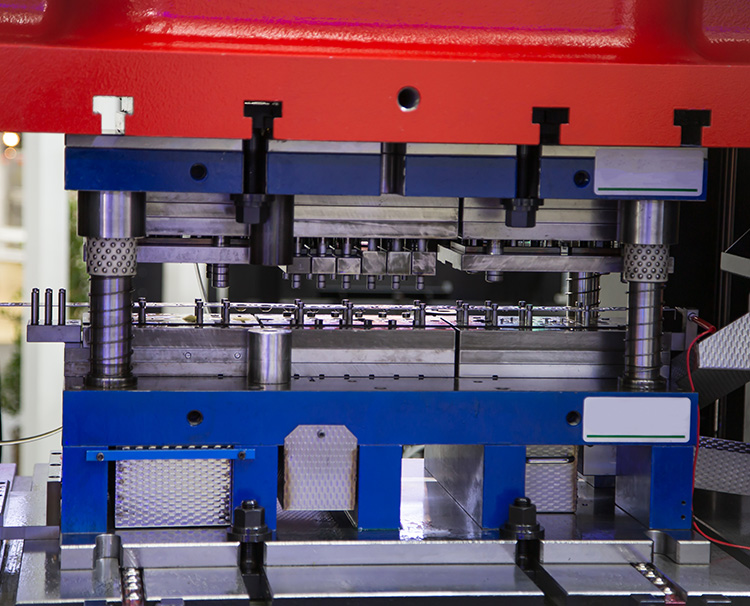

Equipment and Capabilities

Pinnacle Precision Technology has eleven open-back, inclinable presses. Seven of these presses are equipped with automatic material feeders and straighteners capable of accepting material 12 inches wide and up to 3/8 inches thick.

|

|

|||||||||||||||||||||||||||||||||

Secondary Machining and Fabricating Capabilities

| Daewoo Puma 2100 Lathe | Haas VF1 CNC Milling Machine |

| Mitsubishi FA20SM Wire EDM | Haas VF3 CNC Milling Machine |

| Cincinnati XI Press Break | Behringer Precision Band Saw |

| BesCutter Smart Cube with 3kW IPG Fiber Laser Cutter |

|

|